Responsible Sourcing Supplier Program

Hershey works with thousands of suppliers and business partners around the world every day. We count on this network of ingredients and packaging suppliers, co-manufacturers, co-packers, indirect service providers and licensees to deliver goods and services to Hershey in a responsible way. We work with suppliers who commit to and uphold the same high standards to which we hold ourselves – standards of integrity, values and operating principles and to work ethically and sustainably to provide great tasting, high-quality products to our consumers.

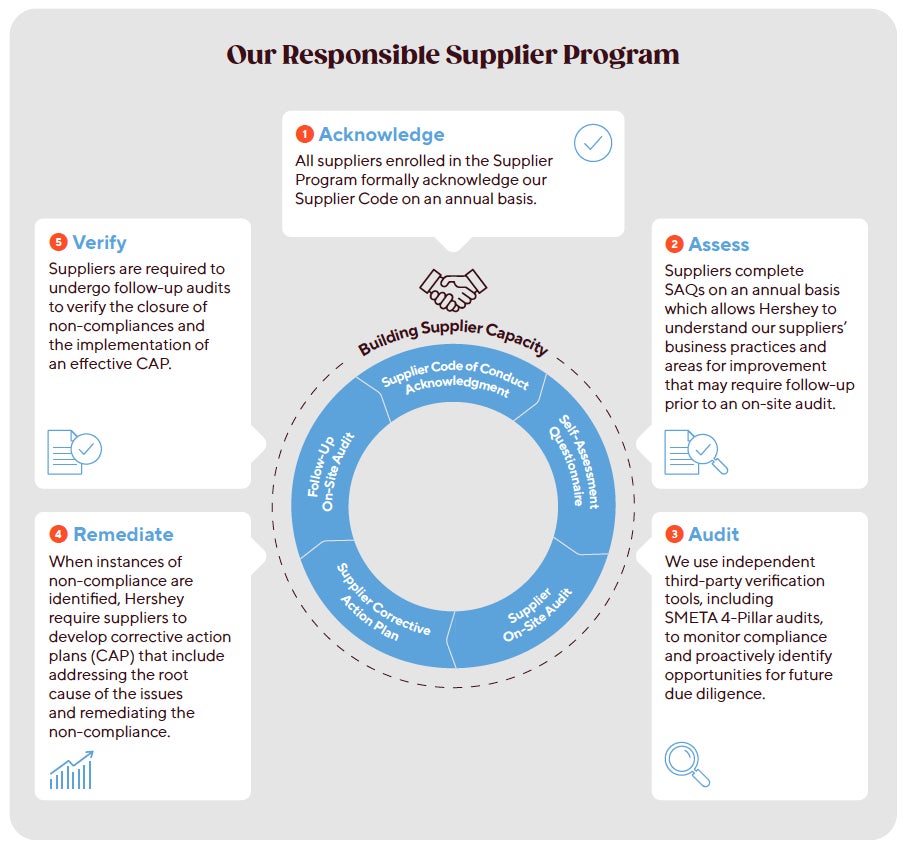

Launched in 2020, our Responsible Sourcing Supplier Program (Supplier Program) aims to proactively manage social compliance, human rights, business ethics and environmental risk across our Tier 1 suppliers by monitoring and verifying compliance with our Supplier Code of Conduct (Supplier Code). Through the Supplier Program, Hershey collaborates with suppliers on continuous improvement through corrective action plans and capability building where needed to drive positive and lasting change for our people, the planet and the long-term sustainability of our supply chain.

Hershey recognizes the size and complexity of our global supply chain spanning from manufacturers, distributors and processers to large-scale agricultural sites, family farms and smallholders. While it is not currently feasible for us to monitor compliance of every Supplier in our global supply chain, we leverage a risk-based approach to assessing compliance against our Supplier Code. We developed our Supplier Program so that we can engage our Tier 1 suppliers around the world who may be at very different stages in their responsible sourcing journey.

Our Responsible Sourcing Supplier Program Approach

Enrolled suppliers must follow a five-step process:

Acknowledge

Our Supplier Code of Conduct reflects Hershey’s values and principles and outlines Hershey’s requirements and expectations with respect to responsible sourcing including our commitments to human rights, the environment, health and safety, business ethics and the development of a diverse and sustainable supply chain. All suppliers enrolled in the Supplier Program formally acknowledge our Supplier Code on an annual basis.

The Supplier Code of Conduct can be downloaded in multiple languages: Bahasa Melayu, Chinese, French, Japanese, Korean, Portuguese, Spanish, Tamil and Telugu.

We have published a Supplier Program Guidebook to assist suppliers in understanding and delivering on the expectations of our Supplier Code and relevant sourcing policies as well as define Critical and Zero Tolerance violations.

The Supplier Program Guidebook can be downloaded in multiple languages: Bahasa Melayu, Chinese, French, Hindi, Japanese, Korean, Portuguese, Spanish, Tamil and Telugu.

Assess

Self-Assessment Questionnaires (SAQs) are an important tool for Hershey to hear directly from suppliers on their own programming efforts and responsible sourcing journeys. The SAQ allows Hershey to understand our suppliers’ business practices and areas for improvement that may require follow-up prior to an on-site audit. Enrolled suppliers are required to complete or update their facility’s Sedex SAQ or equivalent on an annual basis. As described in our Supplier Program Guidebook, Hershey prioritizes the Sedex SAQ as Sedex is a leading nonprofit focused on improving ethical performance in corporate supply chains.

Annually, Hershey assesses our Tier 1 suppliers and sites to continuously enroll those who we identify as high-risk or high priority into the Supplier Program. The supplier risk assessment tool, developed in partnership with human rights NGO Verité, covers four categories of risks: human rights risks based on geography; human rights risks based on value chain; volume of Hershey spend; and supplier continuity risks. We use this tool to assess our Tier 1 ingredient and raw material and packaging suppliers, co-manufacturers, co-packers, licensees and labor service providers.

We conduct responsible sourcing and human rights risk screenings in advance of entering a commercial relationship with ingredient and packaging suppliers; co-manufacturer/co-packers; and Licensing manufacturing sites. The pre-screening process reviews the prospective supplier’s SAQ and/or social compliance audit, depending on risk profile, to assess their management systems related to human rights and labor, health and safety, environment, and business ethics. Potential suppliers may be required to submit corrective actions and/or undergo follow-up verification audits prior to an approval or rejection decision.

Audit

On-site social compliance audits allow Hershey to understand supplier performance and activity – both positive and negative – across the topics of labor, health and safety, environment and business ethics. The audit process opens a dialogue between Hershey and our suppliers for sharing concerns, best practices and where training and investment is needed for continuous improvement.

Our Supplier Program requires suppliers to undergo the Sedex Members Ethical Trade Audit (SMETA) 4-pillar social compliance audit or equivalent by an approved Hershey monitoring firm. As a member of AIM-Progress, Hershey also supports the process of mutual recognition to reduce audit duplication, fatigue and cost.

Audit performance is assessed and scored based on the number and severity of non-compliance issues determined by our internal audit grading matrix. Audit results inform follow-up requirements and timelines for completion. More detailed information about our Critical and Zero Tolerance violations can be found in Appendix A of our Supplier Guidebook.

Remediate

Hershey aims to work with suppliers that share our values. When instances of non-compliance are identified, we require suppliers to develop Corrective Action Plans (CAP) that include addressing the root cause of the issues and remediating the non-compliance. We are also committed to collaborating and working with our suppliers on continuous improvement.

We identify capability-building opportunities to enable suppliers to achieve compliance and improve the lives of workers through direct collaboration with suppliers as well as through our involvement with AIM-Progress and membership with Sedex and the Responsible Labor Initiative.

Verify

Suppliers are required to undergo follow-up audits to verify the closure of non-compliances and the implementation of an effective CAP. Follow-up audit results inform future requirements and timelines.

In 2022, we built a dashboard to provide procurement and supplier relationship managers with real-time access to Supplier Program data, which is then considered in sourcing decisions and supplier discussions.

See our ESG Report for updated progress and data from our Supplier Program.

Hershey Owned Facilities Social Compliance Approach

Our commitment to a responsible supply chain applies equally to the facilities that Hershey owns. We conduct SMETA 4-Pillar audits at all Hershey-owned operations. In 2022, we moved from a time-based (i.e., every three years) to a performance-driven cadence, which is triggered by SMETA 4-Pillar audit performance and required noncompliance remediation. Corrective action plans and follow-up audits are required if non-compliances are identified.

To learn more about our due diligence efforts with labor service providers, please see “Responsible Recruitment & Employment”